Simply Sophisticated

Innovation is the beneficial utilization of knowledge and creativity, in order to discover and realize what does not yet exist.

WE ARE COMMITTED TO THE TRADITION & PRINCIPLES

THAT LED US THROUGHOUT THE YEARS

Founded in 1980 in Shlomi, Israel, Noga Engineering & Technology Ltd. is a global leader in precision engineering tools and systems. With over 40 years of experience, the company specializes in deburring systems, holding systems, and NOGA MT solutions, serving industries such as aerospace, defense, automotive, and general manufacturing. Noga is recognized worldwide for its quality, innovation, and reliable service, with products distributed in over 70 countries through a global network of branches and agents.

SUCCESS ONLY COMES TO THOSE

WHO DARE TO ATTEMPT

SUCCESS ONLY COMES TO THOSE WHO DARE TO ATTEMPT

QUESTIONS AND ANSWERS

Noga program offers a wide comprehensive range of deburring blades.

For every type of deburring blades you can see the drawings showing the suitable applications.

You can find these drawings at the bottom left side of the page.

Please select the blade according to the drawing application were the area marked in red is the area where the blade works.

For some applications there is a selection of blades according to the workpiece material, blade material and grinding angle.

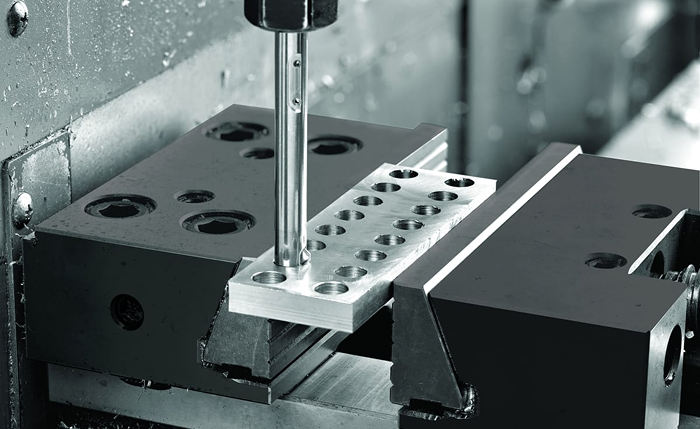

NOGA MT tools are engineered to perform deburring, back counterboring, back countersinking/chamfering, spot-facing, and surface finishing directly on CNC machines, eliminating slow, inconsistent manual operations. By integrating NOGA MT solutions into the machining cycle, manufacturers achieve shorter cycle times, consistent quality, higher repeatability, and reduced labor dependency, while maintaining full process control and traceability.

Noga customers are using different types of indicators, most popular are:

– European Standard – 8mm

– American Standard – 3/8″

– Japanese standard – 6mm

The indicators can be held by dovetail or stem.

Noga Introduced its Universal swivel clamp FA1500 that can hold all sizes(6mm,8mm and 3/8″).

NOGA MT offers dedicated tool families for each operation:

• UBURR – front and back deburring of drilled holes

• UBACK – precision back counterboring and back countersink/chamfering

• UFIBER – controlled burr removal and surface finishing

The optimal solution depends on the material, hole size, geometry, machine type, and production volume. NOGA MT provides expert application support and proven case studies to ensure

EXHIBITIONS AND EVENTS

Need help achieving the perfect finish?

Get guidance on our tools & techniques for cleaner, more accurate results.